Solvent recovery supports various industrial operations to reclaim and reuse solvents effectively. This initiative increases savings, reduces waste, and decreases the demand for new solvent purchases. Industries rely on two solvent recovery methods to manage their resources wisely. Let’s discuss the differences between passive and active solvent recovery to learn which technique is favorable for your operations.

The Fundamental Difference Between Solvent Recovery Methods

Industries use two fundamental types of solvent recovery: passive and active. Passive recovery is a natural process, while active recovery operates via mechanical means.

Choosing the right method depends on several factors, including efficiency, energy consumption, and operational scale. A thorough understanding of these methods allows businesses to optimize their operational strategies and resource management.

How Passive Solvent Recovery Works

Passive solvent recovery uses natural processes—including evaporation and condensation—to capture and reuse solvents. This technique requires minimal energy input because it harnesses ambient conditions to facilitate solvent transformation.

When solvents possess the characteristics that allow them to change states naturally, passive recovery is the best option. Two techniques include open-air drying and natural temperature gradients; these are both cost-effective and straightforward processes.

Benefits of Passive Solvent Recovery

The economic advantage of passive solvent recovery is a primary benefit. Companies can save on energy costs due to the small amount of power required to drive the recovery process. This simplified method reduces the need for complex machinery and extensive maintenance, therefore decreasing operational expenses.

Companies appreciate passive solvent recovery’s ease of implementation because it integrates seamlessly into existing environments. Additionally, it promotes sustainability by lowering the carbon footprint compared to more energy-intensive methods.

Limitations of Passive Solvent Recovery

Despite its benefits, passive solvent recovery has limitations. The process may take a long time to reach desired recovery levels. This could create delays for tasks that require quicker solvent turnaround.

Moreover, its effectiveness is highly dependent on ambient conditions. For example, changes in temperature or humidity can impact the efficiency of this natural process.

Furthermore, passive methods may not suit all solvent types, particularly those requiring specific conditions for evaporation or condensation. It’s important to evaluate each of these concerns before adopting passive solvent recovery into your company’s operations.

Industries and Applications

Industries such as woodworking, textiles, and small-scale manufacturing frequently use passive solvent recovery due to its simple and cost-effective qualities. These sectors work with solvents that evaporate easily under ambient conditions, making passive recovery an ideal solution.

How Active Solvent Recovery Works

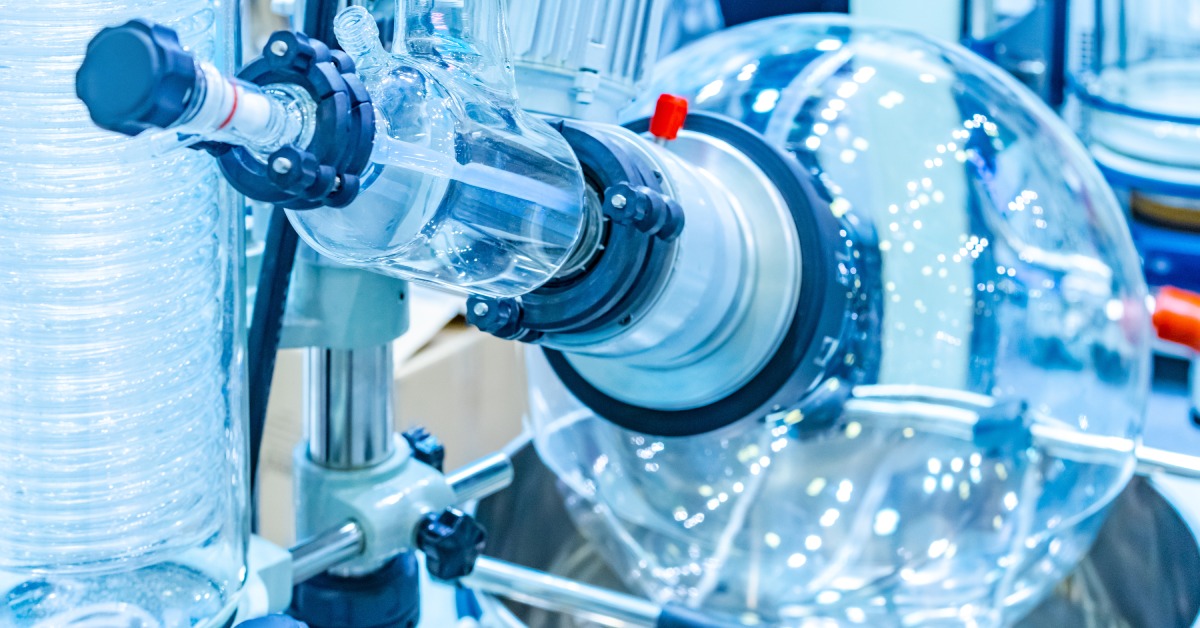

Active solvent recovery uses mechanical techniques, like distillation, to reclaim solvents with heightened efficiency. This method requires external energy sources from solvent recovery systems to drive the reclamation process, enabling precise control over temperature and pressure conditions.

Active recovery adapts to the solvent’s characteristics through mechanical agitation, separation, and purification. Advanced machinery facilitates solvents’ rapid transformation and collection, accommodating various industrial demands.

Benefits of Active Solvent Recovery

Active solvent recovery is the preferred method in many industrial applications. One key advantage is its ability to deliver quick recovery rates for operations that demand rapid solvent turnover. The method offers precise control, allowing industries to ensure consistent solvent quality and purity.

Active recovery supports scalability so businesses can adjust their processes according to production demands without compromising efficiency. Its ability to adapt to different solvent types and conditions enhances operational flexibility.

Limitations of Active Solvent Recovery

Despite its strengths, active solvent recovery comes with disadvantages that companies must consider. The process requires significant energy input that will increase operational costs and environmental impact.

The need for specialized equipment also requires capital investment and ongoing maintenance. Active methods may introduce complex processes into operations, requiring skilled personnel to manage the recovery systems.

Industries and Applications

Industries such as pharmaceuticals, petrochemicals, and large-scale chemical processing rely on active solvent recovery. The method’s capability to maintain stringent quality standards and handle diverse solvent types makes it a favorable option for these applications.

Active recovery is essential in environments where precision and speed are paramount, such as in the production of fine chemicals and in manufacturing electronics. It supports industries that must meet high regulatory standards and achieve efficient resource management.

Key Differences Between Solvent Recovery Methods

The differences between passive and active solvent recovery include their particular processes, energy needs, and effects on different industrial operations.

For instance, small manufacturing setups benefit from the minimal energy use of passive recovery because the solvents naturally evaporate or condense, reducing costs and simplifying operations. It excels in energy efficiency, making it ideal for settings where natural drying meets an operation’s needs without high electricity bills.

On the other hand, active recovery requires mechanical techniques that demand more energy to sustain precise conditions. This method accommodates industries like pharmaceuticals that need quick turnarounds and high-purity levels. Keep in mind that with active recovery comes higher energy consumption due to its reliance on mechanical systems.

Passive recovery offers simplicity with lower maintenance needs, attracting industries focused on minimizing costs and resource use, such as workshops handling easily evaporating solvents. Conversely, active recovery provides speed and control for sectors like electronics manufacturing.

How To Choose a Recovery Method for Your Company

Cost Considerations

Cost considerations can help businesses choose between solvent recovery methods. Passive recovery is a more cost-effective solution due to its minimal energy requirements and simple setup. Industries with tight budget constraints might find this choice appealing.

Active recovery demands a higher initial investment in specialized equipment. However, industries that are willing to invest in advanced technology will benefit from high efficiency and fast processing. This could result in an immense return on investment through enhanced productivity.

Scale and Operational Needs

Smaller businesses or those handling low solvent volumes may find passive recovery sufficient. However, large industries or those with complex solvent requirements typically lean towards active recovery to support large-scale operations by offering precision and adaptability to recover various solvent types.

Environmental Impact

Passive recovery aligns with businesses prioritizing eco-friendly practices due to its low energy consumption and reduced carbon footprint. Active recovery, while energy-intensive, has the potential to support sustainability efforts when it’s integrated with energy-efficient technologies and waste reduction strategies.

Sustainability Goals

Many companies establish sustainability goals that improve resource management and comply with environmental standards. For example, industries that adopt passive recovery can bolster their sustainability credentials by reducing energy consumption and waste. Meanwhile, companies that embrace active recovery can invest in innovations like energy recovery systems to mitigate environmental impact.

Conclusion

Industries have the choice between passive and active solvent recovery for resource management. Passive recovery stands out for its straightforward and cost-effective nature, whereas active recovery excels in rapid, precise results. Assess your business’s demands to make a choice that will transform your business’s productivity and environmental impact.