The printing industry relies on solvents for various applications. From cleaning printing presses to dissolving inks, chemicals support high-quality prints. Managing these solvents efficiently is vital for environmental sustainability, worker protection, and overall operational efficiency of printing businesses. Learn the best practices for solvent management in printing to improve your operations.

Understanding Solvents in Printing

Solvents are substances capable of dissolving solutes, resulting in solutions that are integral to the printing process in some way. In the printing industry, businesses use solvents to clean machinery and thin inks to make them suitable for use.

Here’s a closer look at the roles of some common solvents:

- Alcohols: Solvents like isopropyl alcohol are popular due to their effectiveness in dissolving a broad range of substances and their relatively rapid evaporation rate. They can help adjust ink viscosity and clean equipment.

- Esters: These are known for their strong solvency power, making them effective for dissolving tough ink residues during the cleaning process. Some manufacturers use them in specialty inks due to their drying characteristics.

- Ketones: Ketones,such as acetone, are potent solvents used for cleaning purposes and in ink formulations that require rapid drying. Their aggressive solvency makes them suitable for removing difficult residues.

- Glycol ethers: These are versatile solvents that offer a good balance between solvency strength and safety. They are useful in ink formulations to control drying times and improve ink flow without causing excessive irritation or toxicity risks.

The Importance of Effective Solvent Management

Solvents can be volatile and potentially harmful. For example, excessive solvent exposure can lead to air and water pollution, affecting the immediate working environment and broader ecosystem. This exposure can also pose serious health risks to employees, such as respiratory issues. Effective solvent management helps minimize environmental impact and preserve workplace safety.

Additionally, proper solvent management contributes to printing operations’ cost-effectiveness and operational efficiency by reducing waste and ensuring compliance with environmental regulations.

Selection of Solvents

When selecting solvents, businesses must take into account several critical factors, including boiling point, evaporation rate, and toxicity. This careful consideration helps in choosing solvents that meet the technical requirements of printing processes and minimize environmental and health impacts.

Moreover, opting for eco-friendly solvents can significantly reduce potential hazards. Companies should seek solvents with lower toxicity levels and more favorable environmental profiles to ensure safer workplace conditions and lower ecological footprints. Some eco-friendly solvents include water-based and bio-based solvents, methyl soyate, and dimethyl carbonate. Essentially, it’s important to choose chemicals that have minimal impact on both human health and the environment.

Use of Solvents

Ensuring the proper use of solvents involves adopting techniques that minimize waste and limit worker exposure. Companies can focus on several strategies to optimize solvent usage, including:

- Adjusting printing press settings: Precisely calibrating the printing press’s solvent flow rates and drying times can reduce solvent consumption and emissions.

- Utilizing high-efficiency print heads: In digital printing, using print heads for high-efficiency transfers ensures that more ink or coating reaches the substrate, reducing solvent evaporation into the work environment.

- Implementing enclosed systems for solvent-based inks: Enclosing systems where solvent-based inks are present minimizes solvent evaporation into the air while helping control the workplace temperature and humidity.

- Adopting automated cleaning systems for printing equipment: Automated cleaning systems use solvents more efficiently than manual cleaning, reducing waste and exposure during the cleaning of presses and other printing equipment.

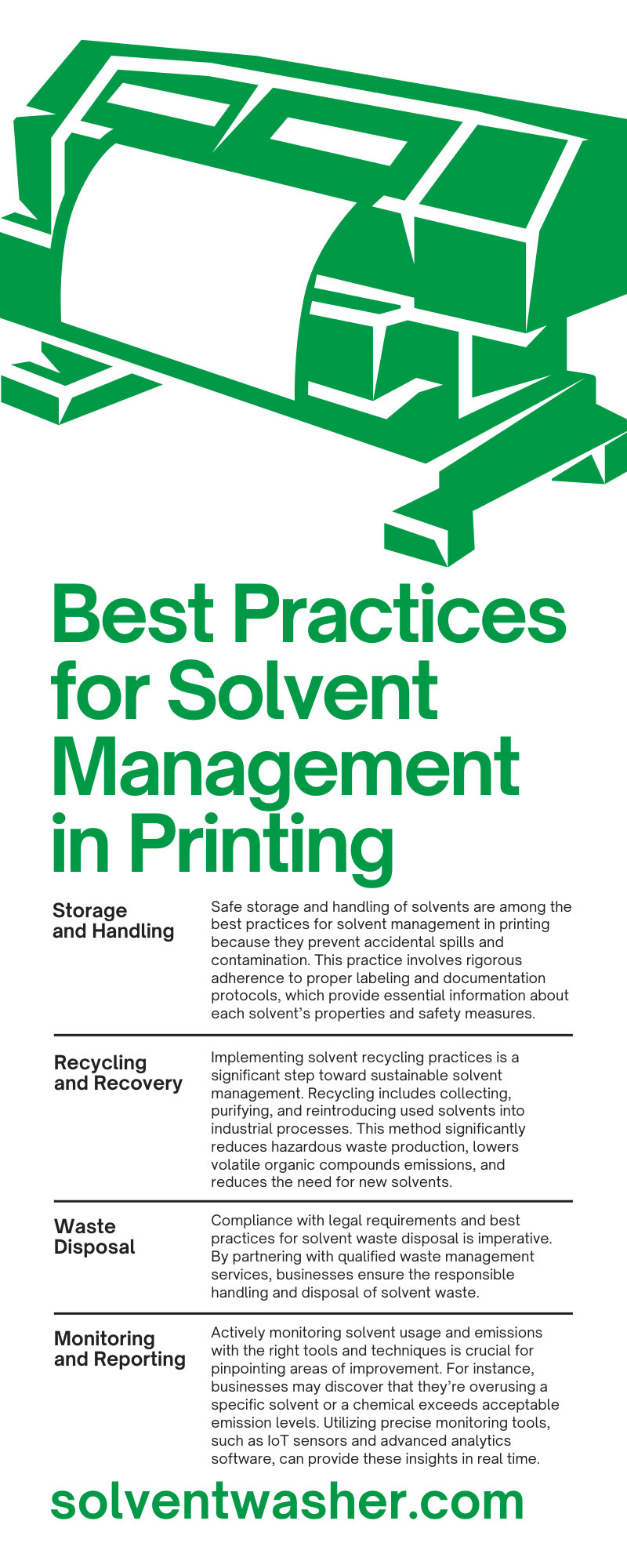

Storage and Handling

Safe storage and handling of solvents are among the best practices for solvent management in printing because they prevent accidental spills and contamination. This practice involves rigorous adherence to proper labeling and documentation protocols, which provide essential information about each solvent’s properties and safety measures.

For example, flammable solvents require labels displaying this information and appropriate handling procedures, such as avoiding open flames and ensuring adequate ventilation. Moreover, material safety data sheets (MSDS) provide detailed information on each solvent’s properties, health hazard data, storage recommendations, and spill-handling procedures.

Common Storage Methods

Adopting common storage methods significantly boosts the safety and efficiency of solvent management. Key practices include segregating solvents, using flammable storage cabinets for volatile chemicals, ensuring proper ventilation, employing spill containment, maintaining temperature control, and regularly inspecting for leaks or damage.

Training and Awareness

It is fundamental to train all staff on safe solvent handling and emergency responses. Continuous training fosters a culture of safety and environmental responsibility within the organization. Companies can achieve this by regularly updating staff on the latest safety protocols related to solvent use. Interactive training sessions, workshops, and drills can significantly enhance staff awareness and preparedness for handling solvents safely.

Recycling and Recovery

Implementing solvent recycling practices is a significant step toward sustainable solvent management. Recycling includes collecting, purifying, and reintroducing used solvents into industrial processes. This method significantly reduces hazardous waste production, lowers volatile organic compounds emissions, and reduces the need for new solvents.

Systems like the 30-gallon solvent cleaning machine from Solvent Waste Management can filter glycol ethers, acetates, and other solvents, effectively removing contaminants and restoring the chemicals to their highest purity.

Waste Disposal

Compliance with legal requirements and best practices for solvent waste disposal is imperative. By partnering with qualified waste management services, businesses ensure the responsible handling and disposal of solvent waste.

These partnerships are essential for adhering to environmental regulations and protecting ecosystems from the potentially harmful effects of solvent disposal. Proper waste management practices may include using specialized containers for hazardous materials and performing regular waste audits.

Monitoring and Reporting

Actively monitoring solvent usage and emissions with the right tools and techniques is crucial for pinpointing areas of improvement. For instance, businesses may discover that they’re overusing a specific solvent or a chemical exceeds acceptable emission levels. Utilizing precise monitoring tools, such as IoT sensors and advanced analytics software, can provide these insights in real time.

Tools and Resources

Besides IoT sensors and advanced analytics software, other resources can support solvent management. In particular, environmental management systems (EMS) can integrate with existing operational processes. The EMS can systematically track, evaluate, and improve a business’s performance, including solvent usage and emissions control.

Businesses can also opt for in-person consultations with environmental consultants or sustainability experts. These experts can offer personalized advice and insights that meet the specific needs and challenges of a business.

In Conclusion

Effective solvent management is important for the printing industry to ensure safety, environmental sustainability, and operational efficiency. By adopting these best practices, businesses can improve their solvent management strategies.

If you’re interested in adding solvent recycling to your processes, contact Solvent Waste Management. We’re here to help you implement solvent recycling solutions that align with your needs, ensuring safety, sustainability, and efficiency. Reach out to our team today to learn more.