Solvents thin paint, clean equipment, and prep surfaces for optimal finishes. However, you may be unfamiliar with the many chemicals that help the painting and coating industries. Each solvent has distinct properties and applications for achieving specific results. Learn about common solvents that businesses use in painting and coating for a deeper understanding of their impact.

The Role of Solvents in Painting and Coating

Solvents are versatile liquids that enable precise control over the viscosity of paint, ensuring uniform coverage and adhesion to substrates. Their ability to modify drying times and improve consistency impacts the quality and durability of the final product.

They also create coatings that withstand harsh conditions such as weather, chemicals, and abrasions. Their adaptability allows manufacturers to develop specialized products tailored to unique requirements.

Turpentine

Turpentine comes from pine tree resin and presents a natural and potent solution for artists and painters. Its composition includes a complex mixture of terpenes, which can break down oil-based substances.

Artists favor turpentine for its unique interaction with oil paints, allowing for smooth, even application across canvases. It excels at thinning paints without compromising their integrity, enabling a range of textures and effects.

In industrial settings, turpentine functions as a solvent in varnishes and as a cleaner for brushes and equipment. Its ability to dissolve oil-based substances makes it invaluable for maintaining tools and achieving desired finishes.

Despite its benefits, turpentine’s strong odor can be overwhelming, causing discomfort in confined spaces. Prolonged exposure to its fumes can cause respiratory issues, necessitating adequate ventilation and protective gear to prevent inhalation. Lastly, the flammable nature of turpentine demands careful storage to mitigate fire hazards.

Toluene

Toluene comes from tolu tree bark or petroleum and can dissolve paints, coatings, and various synthetic materials. It’s a clear, colorless liquid with a distinctive sweet chemical scent. Toluene’s quick evaporation rate aids in rapid drying, making it suitable for processes requiring minimal downtime. Moreover, the solvent dissolves binders and resins, making it integral in formulating high-performance coatings and varnishes.

Due to its toxicity and flammability, handling toluene requires strict safety precautions. Adequate ventilation reduces inhalation risks, while personal protective equipment minimizes skin contact and respiratory exposure.

Mineral Spirits

Mineral spirits, derived from petroleum, offer a versatile solvent solution with a milder profile than turpentine. This solvent undergoes a distillation process, resulting in a clear liquid with varying grades of purity.

The composition of mineral spirits includes hydrocarbons, which contribute to its effectiveness in dissolving and thinning oil-based substances. Its low odor and reduced toxicity make it an appealing option for indoor applications.

Painters frequently rely on mineral spirits for thinning paints and varnishes. In surface preparation, mineral spirits effectively clean and degrease surfaces, providing a pristine base for painting. Professionals also utilize them in cleaning brushes and tools, where their gentle nature preserves the integrity of bristles and metals.

Environmental and Safety Considerations

Mineral spirits pose environmental concerns due to their petroleum base and volatile organic compounds (VOCs). Responsible disposal and usage minimize environmental impact. Proper ventilation and protective equipment guard against exposure, ensuring safe and sustainable use of mineral spirits.

Acetone

Acetone is another common solvent used in painting and coating. This colorless liquid effectively dissolves various organic materials, making it indispensable for preparing and cleaning surfaces before painting.

Acetone’s chemical structure, which includes a carbonyl group, enhances its ability to interact with polymers and adhesives. Its quick evaporation ensures minimal residue, providing a clean surface for coating applications.

In painting and coating, acetone excels at removing old paint, varnishes, and other finishes, ensuring surfaces can handle new applications. Acetone also thins and cleans epoxy resins, enabling an even application of coatings.

Benefits, Innovations, and Handling Precautions

Acetone’s rapid evaporation and strong solvency facilitate quick surface preparation, enhancing productivity and efficiency. Moreover, acetone recycling systems allow users to reclaim and reuse acetone, reducing waste and environmental impact.

Acetone requires careful handling due to its high flammability and potential health risks. Proper ventilation minimizes inhalation hazards, while protective gear like gloves and goggles safeguard against skin and eye irritation. Storing acetone in well-sealed, labeled containers away from heat sources mitigates fire risks.

Naphtha

Naphtha is a versatile hydrocarbon solvent that comes from petroleum. With various grades available, naphtha provides a tailored solution for specific coating requirements. Its rapid evaporation supports quick drying, facilitating efficient coating processes.

Naphtha cleans surfaces, removes grease, and prepares substrates for painting. Its solvent properties enable thorough cleansing, ensuring paint adheres properly and finishes appear flawless.

Naphtha’s ability to dissolve a wide range of substances helps painting and coating professionals. Its rapid drying supports continuous workflow, reducing delays and enhancing productivity. The solvent’s adaptability across various applications makes it an asset in standard and specialized coating operations.

Xylene

Xylene consists of three isomers: ortho-xylene, meta-xylene, and para-xylene. Its high solvency power effectively dissolves a wide range of materials, including adhesives, coatings, and paints. Its moderate evaporation rate allows for controlled drying, preventing the premature setting of paint films.

The solvent thins paints, varnishes, and epoxies, ensuring smooth application and consistency. Xylene also serves as an effective cleaning agent for spray guns and other equipment, maintaining their performance and lifespan.

Xylene offers several advantages, including its ability to dissolve tough substances and ensure even paint application. Its controlled evaporation rate supports precision work, particularly in detailed projects where timing is key. Xylene’s widespread availability makes it a staple in many workshops and studios.

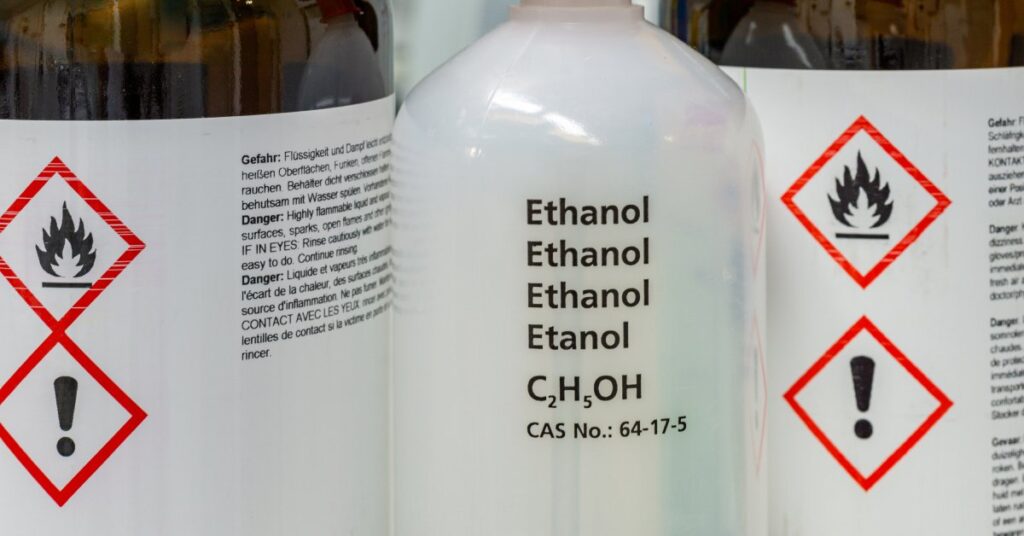

Ethanol

Known for its fast evaporation rate, ethanol effectively dissolves a range of substances, including inks, resins, and coatings. Its clear, colorless appearance and mild odor make it a popular choice in various applications. Ethanol’s compatibility with water enhances its solvency, making it suitable for thinning purposes.

In the painting and coating sectors, ethanol serves as a solvent for water-based and alcohol-based paints. It also removes grease and residues that could affect paint adhesion. Ethanol’s role extends to thinning shellac and other finishes, contributing to the quality of coatings.

Ethanol’s compatibility with various materials enhances its utility, providing a flexible solution for different project requirements. The solvent’s accessibility and affordability make it an attractive option for large-scale operations and individual projects.

What Do These Solvents Have in Common?

These solvents share a common concern: their impact on the environment and health. Emissions from these solvents release volatile organic compounds (VOCs) into the air, which can lead to smog and ground-level ozone. The chemicals deteriorate air quality and pose health risks.

That said, safe handling practices can reduce the negative effects of solvents. This means ensuring good ventilation, using protective gear, and choosing lower-VOC alternatives whenever possible. Through careful practices, the painting and coating industries can lower risks, promoting a healthier environment and safer workplaces.