Sustainable manufacturing isn’t just a trend; it’s a pivotal shift in the business landscape. As regulations tighten and consumer preferences evolve, the pressure for manufacturers to lower their carbon footprint intensifies. Fortunately, eco-friendly practices are easy to implement and can improve productivity. If you’re interested in practical and actionable strategies, learn how manufacturers can reduce their carbon footprint now!

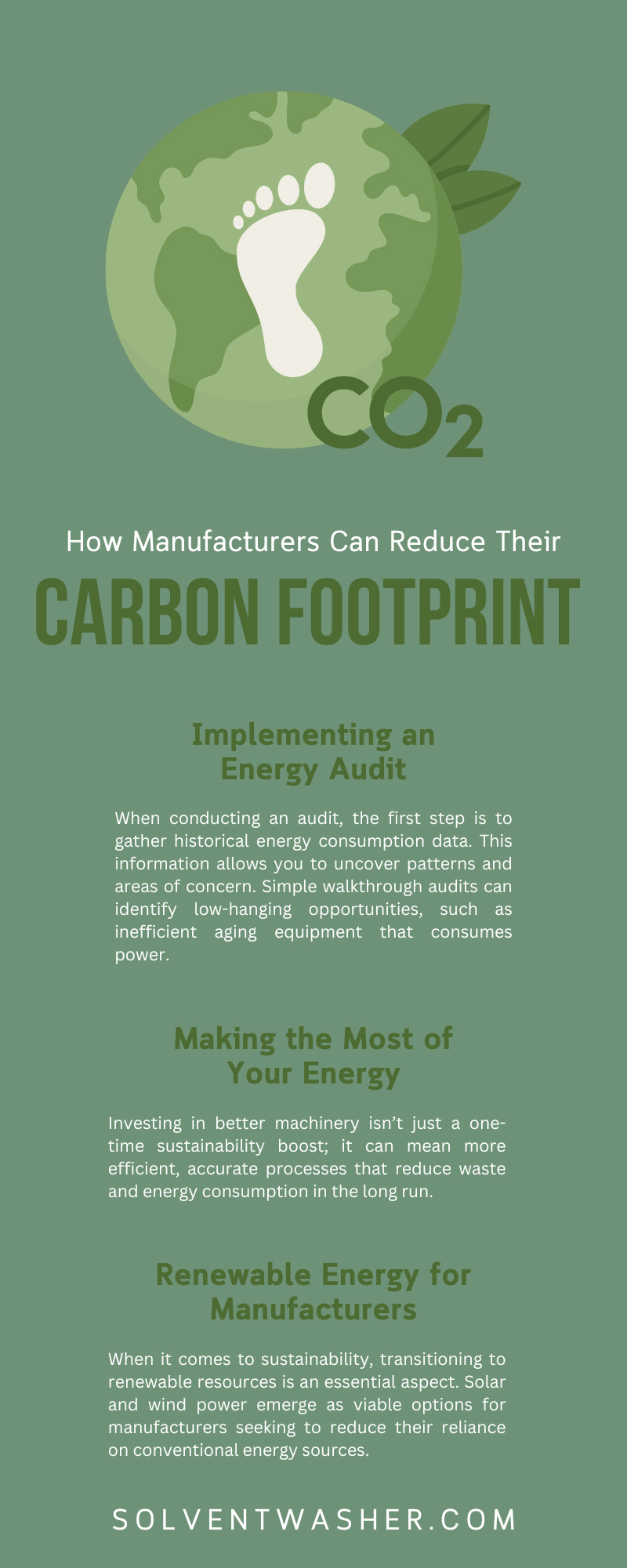

Implementing an Energy Audit

Before reducing carbon emissions, you must understand where and how your company generates them. An energy audit allows you to inspect your manufacturing processes and energy usage comprehensively, so you can pinpoint inefficiencies.

When conducting an audit, the first step is to gather historical energy consumption data. This information allows you to uncover patterns and areas of concern. Simple walkthrough audits can identify low-hanging opportunities, such as inefficient aging equipment that consumes power.

Once you have a baseline assessment, you can conduct further analysis to identify potential inefficiencies and opportunities for optimization.

Uncovering Efficiency Opportunities

Trained auditors can examine building envelopes, insulation, HVAC systems, and lighting to identify potential energy savings. By inspecting these areas thoroughly, auditors can uncover opportunities for improvement that you may not notice.

For some manufacturers, simple measures such as switching to LED lighting or upgrading to energy-efficient motors can yield immediate savings, simultaneously reducing operational costs and environmental impact.

When it comes to industrial facilities, a comprehensive audit can reveal significant opportunities for energy optimization. This may include identifying inefficient processes that facilities can upgrade to more energy-efficient alternatives and uncovering potential areas for renewable energy integration.

Making the Most of Your Energy

Manufacturers can reduce their carbon footprint by improving their energy usage. Upgrading machinery, optimizing workflows, and embracing cutting-edge technologies are all part of the toolkit for the eco-savvy manufacturer.

Investing in better machinery isn’t just a one-time sustainability boost; it can mean more efficient, accurate processes that reduce waste and energy consumption in the long run.

For example, upgrading to more advanced machinery with better automation and precision can streamline production workflows, significantly reducing material wastage and energy usage over time. This aligns with sustainable practices and contributes to cost savings and enhanced environmental stewardship.

Furthermore, implementing energy monitoring systems and automation tools can significantly optimize your energy usage. These systems provide real-time data that empowers you to make on-the-fly adjustments, ensuring peak efficiency and proactive management of energy consumption.

By integrating these technologies into your infrastructure, you can visualize energy consumption patterns and trends meaningfully, facilitating regular review and analysis of energy data to identify potential inefficiencies and opportunities for optimization.

Renewable Energy for Manufacturers

When it comes to sustainability, transitioning to renewable resources is an essential aspect. Solar and wind power emerge as viable options for manufacturers seeking to reduce their reliance on conventional energy sources.

Purchasing solar panels or wind turbines is expensive, but the long-term benefits are undeniable. Along with cost savings on energy bills, manufacturers embracing renewable energy can reduce their reliance on traditional power grids. They may gain positive brand recognition for their commitment to sustainable practices.

Powering Partnerships

Not every manufacturer can install a wind turbine or a solar farm on-site, but that doesn’t mean you can’t benefit from renewable energy. By joining forces with green energy providers, you can substantially reduce your environmental impact.

For example, partnering with renowned companies like General Electric Co. or NextEra Energy can offer manufacturers access to clean and renewable electricity sources without the need for extensive on-site infrastructure.

In addition, the option to purchase renewable electricity directly from power suppliers or independent clean power generators, as well as participation in green power programs, provides manufacturers with a variety of avenues to embrace renewable energy and contribute to a sustainable future.

Implementing Solvent Recycling

Solvent recycling is another opportunity for manufacturers to lower their carbon footprint. Solvent recycling is the process of recovering and reusing processed chemicals, thereby reducing waste and environmental impact.

By using solvent recycling machines, manufacturers can effectively reduce the volume of waste generation during production. This not only aligns with environmentally sustainable practices but also contributes to cost savings and resource efficiency!

Minimizing Materials and Packaging Waste

The products that leave your factory should be as sustainable as the processes that create them. Using recycled materials and minimizing packaging waste can improve your processes.

For instance, utilizing recycled plastic in your products can close the loop on waste in your manufacturing process.

Minimizing packaging is an eco-friendly strategy and a more efficient use of resources within your facility. By reducing excess packaging, you lower the quantity of materials you need and decrease shipping costs through smaller, lighter boxes.

Sustainable Supply Chains

Manufacturing is only one part of the production cycle. Every product is the result of a complex chain of processes and materials. Reducing the carbon footprint of your supply chain and logistics is as crucial as greening your factory floor.

Mapping your supply chain can reveal significant opportunities for reducing carbon emissions. Local suppliers, optimized transportation routes, and using electric or hybrid delivery vehicles are all steps toward a more sustainable supply chain.

By working with your suppliers to adopt sustainable practices, you can ensure that the entire supply chain aligns with your environmental goals. This can include everything from materials sourcing to energy use in manufacturing and packaging.

Engaging Employees for a Sustainable Culture

The most efficient machines and optimized processes can’t fully achieve a sustainable operation without a workforce committed to the cause. Employee engagement and education are vital to any green manufacturing strategy.

Fostering a culture where employees are aware and empowered to champion sustainability can lead to innovative, employee-led solutions that have a profound impact on your carbon footprint. For example, employees may introduce resource-efficient processes, waste reduction strategies, and energy-saving measures within the organization.

Tracking and Reporting Your Progress

Establishing clear sustainability targets and implementing robust monitoring systems are essential for managing and demonstrating commitment to the green agenda. “What gets measured gets managed,” as the saying goes, emphasizing the importance of quantifiable benchmarks in sustainability efforts.

Measurable targets, such as reducing energy consumption by a specific percentage or eliminating the use of certain materials, provide a concrete framework for sustainability goals, guiding organizations toward tangible environmental impact.

Investing in energy monitoring systems and conducting periodic audits can help. Monitoring allows you to track progress, identify areas where things fall short of targets, and make the necessary adjustments to realign with sustainability objectives.

Overall, by actively measuring and managing sustainability targets, organizations can drive continuous improvement, enhance their environmental performance, and contribute meaningfully to the global sustainability movement!

Eco-friendly practices can create tangible value for your business. From saving on energy costs to enhancing your brand reputation, a commitment to sustainability can unlock new opportunities and drive your enterprise forward.